1

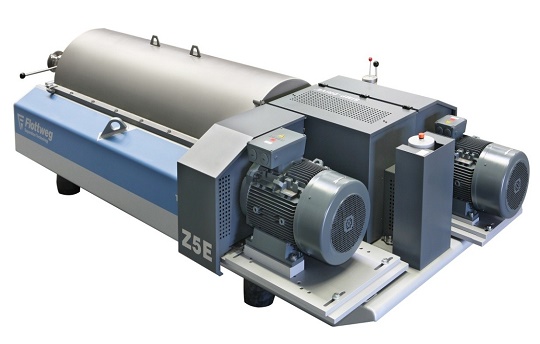

Having delivered its first decanter in 1956, Flottweg has sinc become one of the leading decanter manufacturers in the world. Its headquarters, located in a city called Vilsbiburg, is near Munich, Germany. Unlike many of its competitors, Flottweg continues to design, manufacture and assemble its machine in Germany to maintain the superb quality of its machine. It is no surprise that Flottweg machine are renowned for its reliability and durability. To distinguish it from its competitors, Flottweg has a number of patented features that will assit the performance as well as the ease of operation of its machines, for example, the Variable Impeller System which enables users to change the liquid-liquid separation line at the convenience of machine running at full speed. Flottweg first entered the Indonesia market in 1981 in which it supplied machines to a customer in Norrth Sumatra, Indonesia. These machine are still in operation until today. Over the span of 35 years, Flottweg and PT. Numalos Abadi have jointly sold in excess of 500 units of machines in Indonesia.

2

Having been in the industry for over 55 years, Krebs has been a world leader in cyclones, and centrifugal slurry oumos, highly reputable for its innovative engineering and quality products. In 2007 , Krebs joined the FLSmidthgroup of companies and is now know as FLSmidth Krebs, in Indonesia , PT. NumalosAbadi has had a very good and successful business relationship with FLSmidth Krebs since 2006, resulting in many successful sales of desanding cyclones to many major palm oil companies in Indonesia. Originally used in the mining industry, FLSmidh Krebs’ g-Max desanding cyclones are not only famous for its separation efficiency and effectiveness, but also for its robustness, endurance and reliability.

3

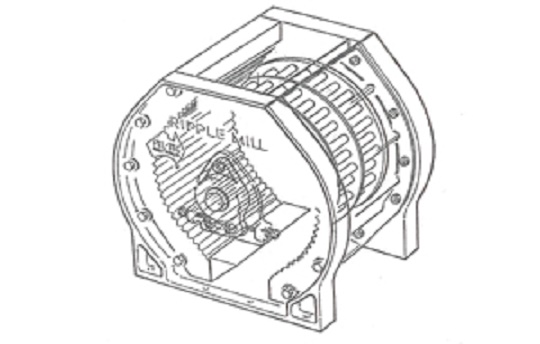

Pel-Tec Ripple Mill was first introduced in the palm oil application in Indonesia in 1984. The use of a rotating balanced rotor composed in squirrel cage design and two stationary semi-circular ripple plates made it a pioneering technologyin nut cracking in the palm oil mills at the time. Pel-Tec Ripple Mill eliminates the need for nut conditioning, i.e. the need to dry the nuts sufficiently to loosen kernels and the cool them to harden the shell, which is required when using the more traditional centrifugal crackers. PT. Numalos Abadi has had many successful sales of Pel-Tec Ripple Mills to many palm oil customers who demand high quality, durability and reliability.

4

1